- Process Capabilities

Process Capabilities

-

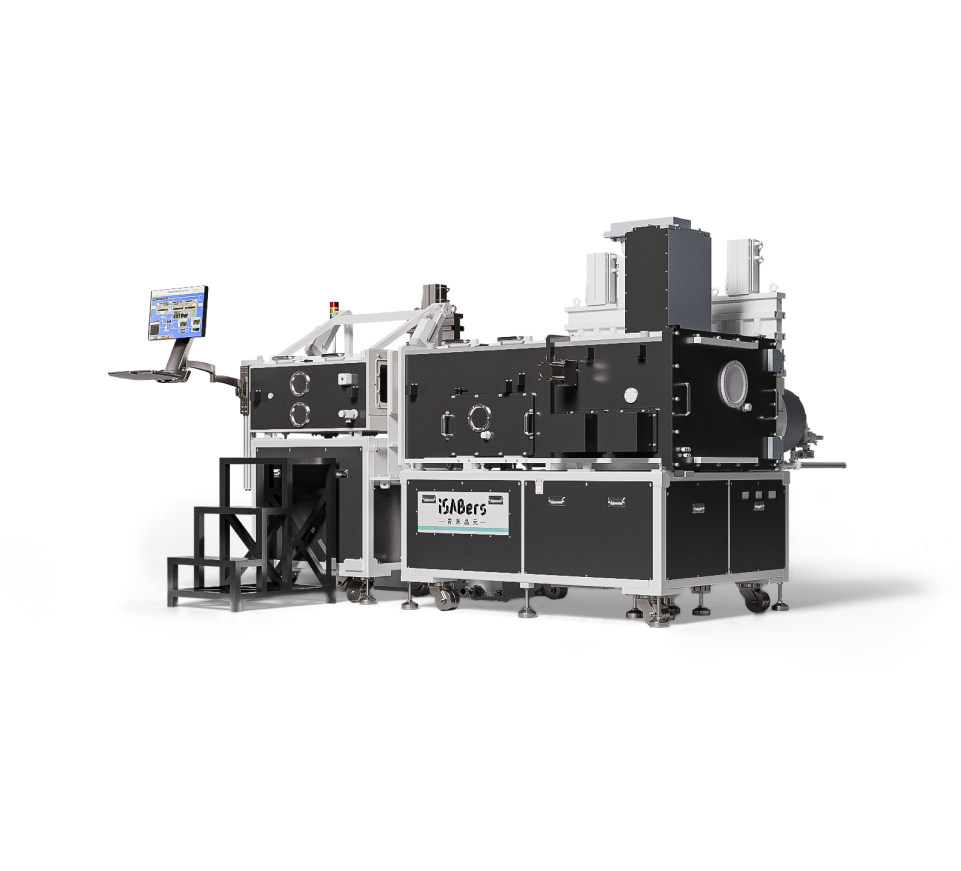

- Ion Implanting

- Ion Implanter

- Wafer size: 4, 6, 8, 12 inch and non-standard shaped materials

- Implant energy: 5~210Kev

- Implant dose: 5E11 ~ 1E17 ions/cm²

- Implant angle: Tilt: 0°~60°, Twist: 0°~359°

- Processed wafer types: SiC, Si, LN, LT, Diamond

- Main Function:

- Complete the doping modification of H, P, and He elements through ion implanting.

-

- Bonding

- Room - Temperature Bonding Machine

- Wafer Size: 4、6、8 inch

- Wafer Thickness: <1000µm

- Alignment Accuracy: X,Y≤70µm、θ≤0.2deg

- Bonding Energy: 1.0-2.0 J/m²

- Processed Wafer Types: 4H-SiC, Poly- SiC, Si, SiO₂, LT, LN, Quartz, Glass, Sapphire, InP, YAG, GaAs,etc.

- Main Function:

- Homogeneous and Heterogeneous Material Bonding

- Hydrophilic/ Hybrid Bonding Machine

- Wafer Size: 6、8 inch

- Wafer Thickness: 6inch≤700µm 8inch≤800µm

- Wafer Thickness: 1.4 - 2.0 J/m²

- Processed Wafer Types: Si, SiO₂, LT, LN, InP, GaAs, SiN,etc.

- Main Function:

- Homogeneous and Heterogeneous Material Bonding

- Thermocompression Anodic Bonding Machine

- Wafer Size: 4, 6, 8, 12 inch

- Wafer Thickness: 0.3 - 3mm

- Alignment Accuracy: ≤ 0.5mm (mechanical alignment), ≤ 2μm (optical alignment)

- Bonding Energy: ≥ 2.0 J/m²

- Processed Material Types: Si, Au, Ag, Cu, AuSn, AlGe, SnAg, AuGe, AuIn, AuSi,etc.

- Main Function:

- Thermocompression bonding of metallic materials, eutectic material bonding, anodic bonding

- Temporary Bonding Machine, Debonding Machine

- Wafer Size: 4, 6, 8, 12 inch

- Wafer Thickness: 0.3 - 3mm

- Processed Wafer Types: Si, SiO₂, Glass, Sapphire, GaAs, InP, etc.

- Debonding Methods: Thermal Sliding (4 - 8 inch), Laser (4 - 12 inch)

- Main Function:

- Temporary bonding and debonding

-

- Grinding-based thinning

- Grinding Machine

- Wafer Size: 4, 6, 8 inch

- Wafer Thickness: < 2200μm

- Equipment Capability: TTV < 1μm, Ra: Si/LN/LT < 10nm, Ra: SiC < 3nm

- Processed Wafer Source Types: Monocrystalline SiC, Polycrystalline SiC, Si, LN, LT, SiO₂, YAG, SP

- Main Function:

- Remove the excess material on the back of the wafer to effectively reduce the wafer packaging volμme, lower the thermal resistance, and improve the heat - dissipation performance of the device.

-

- CMP

- Chemical - Mechanical Polishing

- Wafer Size: 6, 8 inch

- Wafer Thickness: 290 - 1100μm

- Equipment Capability: Roughness < 0.2nm (Polycrystalline SiC roughness < 0.5nm), THK Range < 400A

- Processed Wafer Source Types: Monocrystalline SiC, Polycrystalline SiC, Si, LN, LT, SiO₂ and other composite substrates

- Main Function:

- Flatten the uneven thin - film on the wafer surface, achieving the polishing function of the thin - film.

-

- Oxidation

- Oxidation Furnace

- Wafer Size: 6 inch

- Wafer Thickness: 350 - 750μm

- SIO₂ thickness: 0 - 1μm

- Processed Wafer Types: Silicon Wafer

- Main Function:

- Oxidize silicon - based materials

-

- Poly-Si

- LPCVD Tube

- Wafer Size: 6 inch

- Wafer Thickness: 500 - 750μm

- Deposition thickness : 0 - 1.3μm

- Processed Wafer Types: Silicon Wafer

- Main Function:

- Grow poly-Si layersof silicon - based materials

-

- Trimming

(Ultra - Hard Material Polishing)

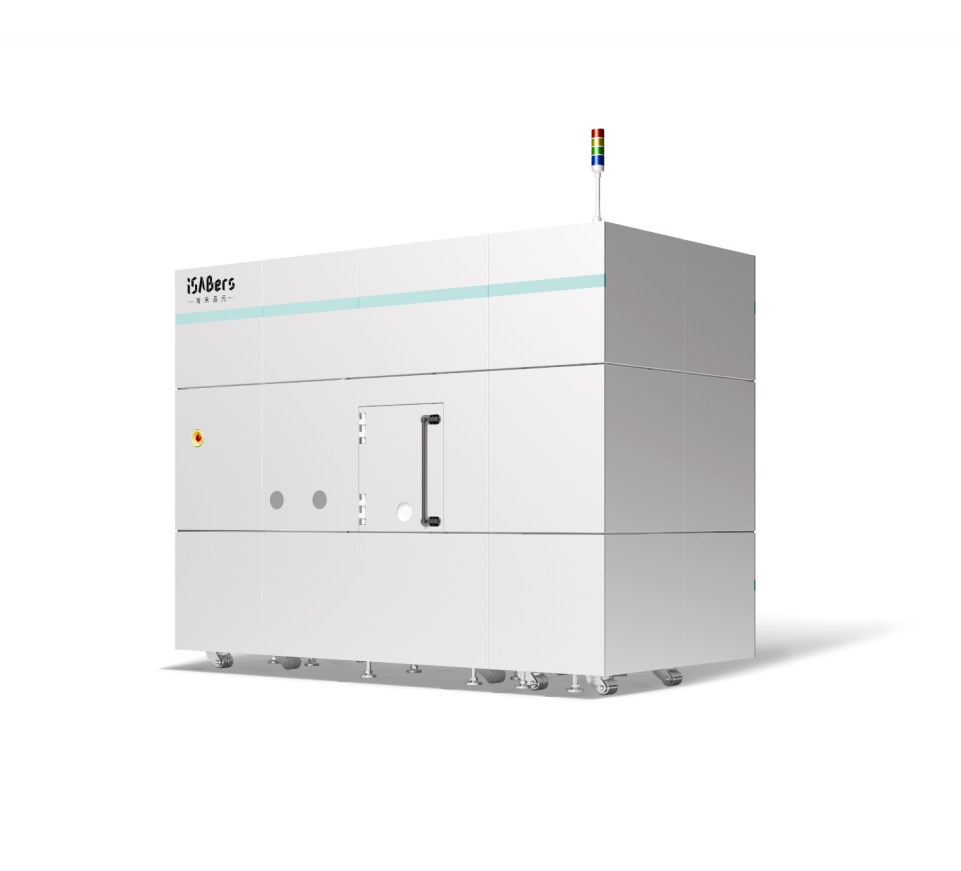

- Ultra - Atomic Beam Polishing Equipment

- Wafer Size: ≤ 8 inch and non-standard shaped materials

- Wafer Thickness: < 1000μm

- Equipment Capability: Polishing

- Processed Wafer Types: unlimited

- Main Function:

- Non - destructive polishing of diamond and various materials to reduce roughness

-

- Annealing

- Annealing Furnace

- Wafer Size: 6 inch

- Wafer Thickness: < 1350μm

- Equipment Capability: Temperature Range: ≤ 1050°C

- Furnace Atmosphere: N₂, Ar

- Processed Wafer Types: Diamond, Single - crystal SiC, Poly - crystal SiC, SOI and Other Composite Substrates

- Main Function:

- Used for the separation of homogeneous and heterogeneous composite substrate wafers

- Annealing Furnace for Defect Repair

- Wafer Size: 6, 8 inch

- Wafer Thickness: < 1350μm

- Equipment Capability: Temperature Range: ≤ 2000°C

- Furnace Atmosphere: N₂, Ar

- Processed Wafer Types: Diamond, 4H-SiC, Poly-SiC, SOI and Other Composite Substrates

- Main Function:

- Used for processes such as defect elimination, impurity activation, and silicide formation after ion implantation in silicon and compound semiconductor materials

-

- Cleaning

- Single-Wafer Cleaning Machine

- Wafer Size: 4, 6, 8 inch

- Wafer Thickness: 200 - 2000μm

- Equipment Capability:

- Particle count SIC(@≥0.3μm) ≤ 30ea after cleaning;

- Particle count SI(@≥0.3μm) ≤ 10ea after cleaning;

- Metal content < 5.0E+10 atoms/cm²

- Processed Wafer Types: Si/LT/LN/SiO₂/SiC/Quartz/Multilayer Bonded Wafers

- Main Function:

- Implement the standard single wafer cleaning process: successively remove organic contamination, particle contamination, metal contamination, and the natural oxide layer on the wafer surface.

- RCA Manual Cleaning Machine

- Wafer Size: 4, 6, 8 inch

- Wafer Thickness: 200 - 1000μm

- Equipment Capability:

- Particle count SIC(@≥0.3μm) ≤ 200ea after cleaning;

- Particle count SI(@≥0.3μm) ≤ 20ea after cleaning;

- Metal content < 5.0E+10 atoms/cm²

- Processed Wafer Types: Si/LT/LN/SiO₂/SiC/Quartz/Multilayer Bonded Wafers

- Main Function:

- Implement the standard RCA cleaning process: successively remove organic contamination, particle contamination, metal contamination, and the natural oxide layer on the wafer surface.

-

- Chamfering

- Micro-Chamfering Machine

- Wafer size: 6, 8 inch

- T-type : Width: ≤3mm, Depth: <700μm

- R-type: Difference in top - bottom amplitude <70μm, Diameter difference <50μm

- Wafer thickness(T-type): <1200μm

- Wafer thickness(R-type): 350-600μm

- Processed wafer types: 4H-SiC, Poly-SiC, Si, SiO₂, YAG, SP

- Main Function:

- R-type and T-type Wafer chamfering operation

-

- Testing

- Wafer Defect Inspection Machine

- Wafer Size: 4, 6, 8 inch

- Wafer Thickness: 290 - 1000μm

- Equipment Capability: BF&DF&PL Defect Detection for Particles 0.2μm and above

- Processed Wafer Types: Si, SiC, LT, LN, SiO₂ and other composite substrates

- Main Function:

- Detect the defect on the wafer surface

- Thin - Film Thickness Measuring Instrμment

- Wafer Size: Unlimited

- Wafer Thickness: Unlimited

- Equipment Capability: Film thickness range 10nm - 250μm

- Processed Wafer Types: Any material with film - layer structure

- Main Function:

- Detect the film - layer situation of wafers

- Flatness Measuring Instrμment

- Wafer Size: 4, 6, 8 inch

- Wafer Thickness: 300 - 1000μm

- Equipment Capability: TTV/LTV/Warp/Bow/THK, etc.

- Processed Wafer Types: Unlimited

- Main Function:

- Detect the Geometric Parameters of wafers

- Atomic Force Microscope (AFM)

- Wafer Size: 4, 6, 8 inch and non-standard shaped materials Wafer Thickness: < 3000μm

- Equipment Capability:

- Minimμm test size: 5μm*5μm;

- Ra < 10nm; Step height < 5μm, Visible step locations are present. Step width range is less than 50 μm.

- Processed Wafer Source Types: Unlimited

- Main Function:

- Obtain the surface morphology of samples by utilizing the relationship of atomic forces between the probe and the sample.

- Ultrasonic Microscope

- Wafer Size: Unlimited

- Wafer Thickness: Unlimited

- Equipment Capability:

- Minimμm resolution: 0.5μm. Output Map and void ratio.

- Processed Wafer Types: Unlimited

- Main Function:

- Used to observe delamination, voids, bubbles, gaps, impurity particles and other defects inside the bonded wafer.

- 3D Hybrid Confocal Scanning Microscope

- Wafer Size: Unlimited

- Wafer Thickness: Unlimited

- Equipment Capability:

- Step height: 5 - 50μm.

- Defect characterization: above 0.3μm.

- Roughness: μm level

- Processed Wafer Types: Unlimited

- Main Function:

- Obtain the 3D surface morphology of the sample, and effectively characterize surface roughness and micro - structure geometric dimensions.

- Inductively Coupled Plasma Mass Spectrometer (ICP - MS)

- Wafer Size: Unlimited

- Wafer Thickness: Unlimited

- Equipment Capability: Measure metals such as Li, B, Na, Mg, Al, K, Ga, Ti, Cr, Ni, Cu, Fe, Zn, Ce; Detection limit is in the ppt level

- Processed Wafer Source Types: Unlimited

- Main Function:

- Detect metallic elements in samples

- Non - Contact Resistivity Meter

- Wafer Size: 2, 4, 6, 8 inch

- Wafer Thickness: 300 - 800μm

- Equipment Capability: Resistance range: 0.035 - 10³ Ω/sq.

- Processed Wafer Types: Si/SiC

- Main Function:

- Detect the resistivity of samples

- Void Infrared Detector

- Wafer Size: 2, 4, 6, 8, 12 inch

- Wafer Thickness: Unlimited

- Equipment Capability: Measure the nμmber and size of voids

- Processed Wafer Types: Si - Si, Si - SiO₂, LT/LN - Si, LT/LN - SiO₂, SiC, etc.

- Main Function:

- Detect the void level of samples

- Four - Probe Sheet Resistance Meter

- Wafer Size: 2, 4, 6, 8, 12 inch

- Wafer Thickness: ≤1mm

- Equipment Capability: Measurement accuracy ≤ 1%.

- Sheet resistance measurement range: 1 mΩ/sq- 8x105Ω/sq

- Processed Wafer Types: PN-junction silicon material

- Main Function:

- Measure the Sheet Resistance of the wafer surface

-

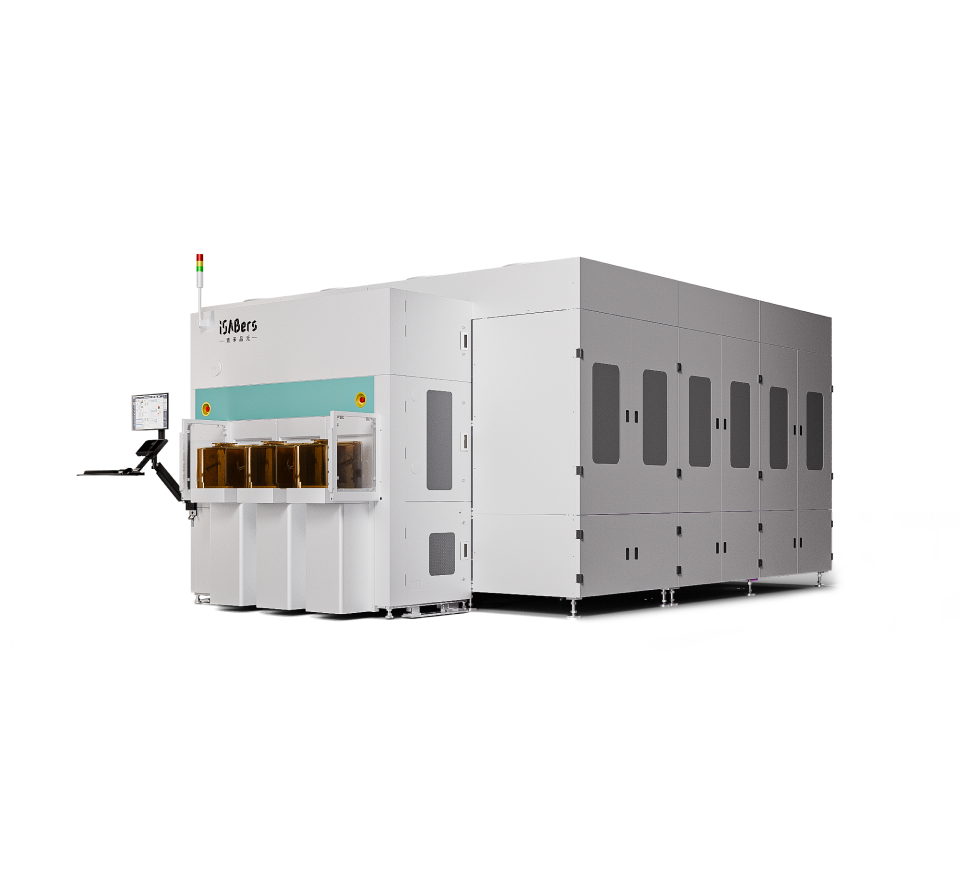

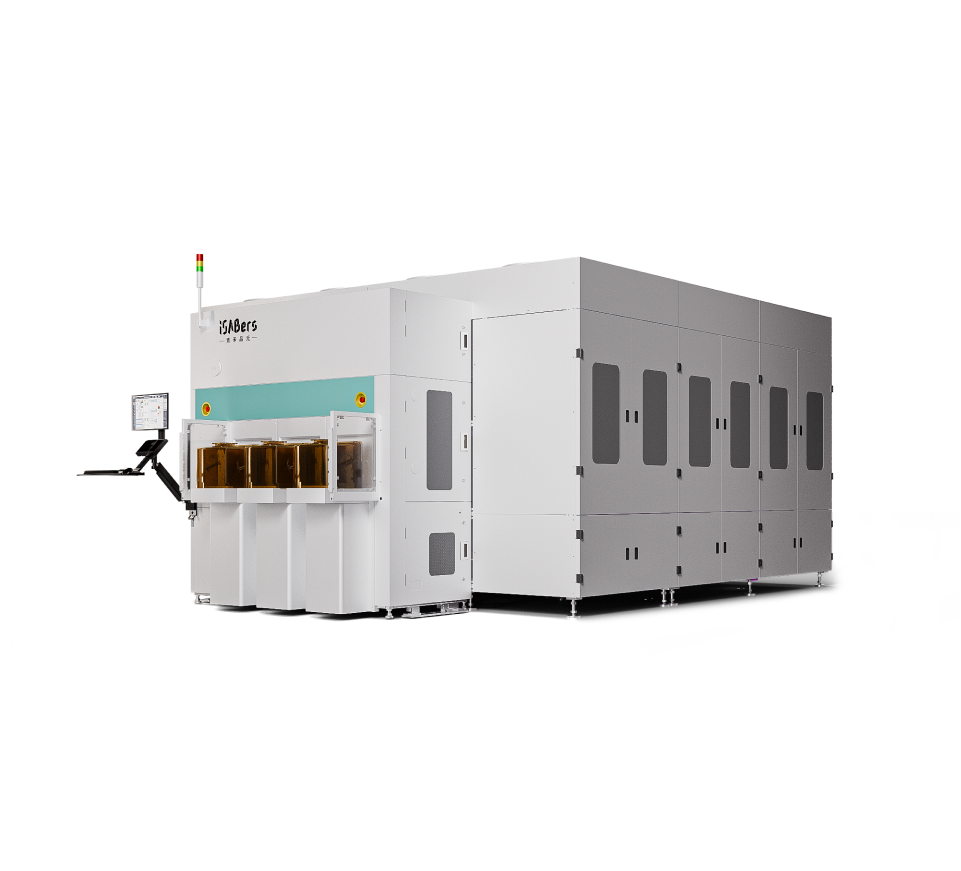

- Trim

- Ion Beam Polishing and Etching Machine

- Wafer Size: 4, 6, 8 inch

- Wafer Thickness: 400 - 1000μm

- Equipment Capability: Increase THK sigma by more than 3 times (SiO₂ THK Range < 10Å; LT0I/LN0I range < 100Å; SiC0I range < 1000Å. The range is affected by the previous value of the film - layer material)

- Processed Wafer Types: SOI, SiO₂, SiC composite substrates, LNOI, LTOI and other film - coated materials

- Main Function:

- Etching various thin - film materials and performing film - thickness adjustment